Leading jeans maker

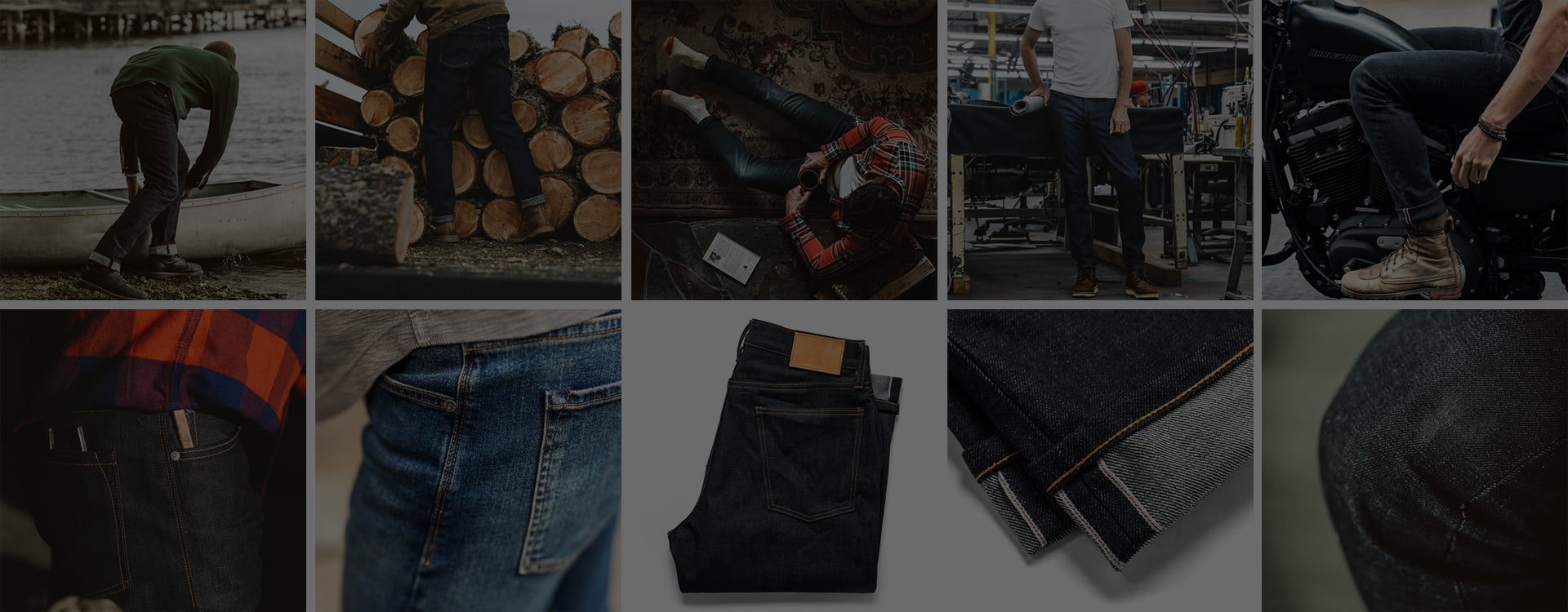

As an experienced jeans manufacturer, MAGICSFASHION pays more attention to the choice of fabric and the design of the pattern and washing.

In the dynamic world of denim fashion, MAGICSFAHSION stands as a beacon of excellence, committed to delivering the finest quality jeans that blend style, comfort, and durability. Our factory is a hub of innovation and craftsmanship, where every pair of jeans is a testament to our unwavering dedication to perfection.

State - of - the - Art Sewing Equipment

At the heart of our production process lies a comprehensive range of state - of - the - art sewing equipment. From high - speed lockstitch machines that ensure strong and precise seams to specialized overlock machines that provide a clean and finished edge, our equipment is designed to handle the demands of denim manufacturing with ease. Our sewing machines are equipped with advanced features such as automatic thread trimming, adjustable stitch length, and programmable sewing patterns, allowing us to achieve the highest level of accuracy and consistency in every stitch.

Sewing before washing

Seamer's exquisite skills: After the fabric is cut, the seamer operates a high-speed flat sewing machine for sewing. The machine quickly and accurately stitches pieces of denim to create strong, straight seams that can withstand wear and tear in everyday wear. Sewers not only pursue speed, but also pay attention to the quality of each stitch, ensuring that the thread is evenly distributed and the tension is appropriate. A well-sewn seam can both connect the fabric and add durability and style to the jeans.

Perfect washing process

Washing is a key step in the denim manufacturing process as it gives jeans their unique look and feel. We offer a variety of innovative washing techniques, including plain washing, enzyme washing, sand washing, stone washing, acid washing, monkey spray, cat whisker rubbing, carving, cutting, ozone baking and sand blasting to create different effects and appearances and so on. Our washing process is strictly controlled to ensure consistent results and minimize environmental impact. Whenever possible, we use environmentally friendly washing methods and chemicals without compromising the quality and appearance of our jeans. Whether you prefer a classic faded look or a bold worn out style, our wash technology can help you achieve the desired result.

Sewing after washing

After the jeans are washed, we also need to sew leather plates, labels and other objects, which are easy to be destroyed in the washing process.

Quality Control

Our team contains experts in quality control with independent autonomy that are in charge of the entire production phase, to guarantee the state of high quality of clothes in your production.

1- QC when the fabrics arrive at our warehouse

2- QC in pattern

3- QC on cut bulk production

4- QC on special sew operations, final accessories, ironing, individual packaging & labeling

Styles Display

You can directly choose the following styles for manufacturing, you can also provide your design drawings, we can help you turn your ideas into reality.

LET’S COLLABORATE

Work with us . Let's talk!

-

Blue-gray ninth men's jeans 69

Regular price $0.00Regular priceUnit price / per$0.00Sale price $0.00 -

men's jeans 13

Regular price $0.00Regular priceUnit price / per$0.00Sale price $0.00 -

men's jeans 15

Regular price $0.00Regular priceUnit price / per$0.00Sale price $0.00 -

men's jeans 17

Regular price $0.00Regular priceUnit price / per$0.00Sale price $0.00 -

men's jeans 21

Regular price $0.00Regular priceUnit price / per$0.00Sale price $0.00 -

men's jeans 23

Regular price $0.00Regular priceUnit price / per$0.00Sale price $0.00 -

men's jeans 33

Regular price $0.00Regular priceUnit price / per$0.00Sale price $0.00 -

men's jeans 34

Regular price $0.00Regular priceUnit price / per$0.00Sale price $0.00 -

men's jeans 37

Regular price $0.00Regular priceUnit price / per$0.00Sale price $0.00 -

men's jeans 43

Regular price $0.00Regular priceUnit price / per$0.00Sale price $0.00 -

men's jeans 45

Regular price $0.00Regular priceUnit price / per$0.00Sale price $0.00 -

men's jeans 46

Regular price $0.00Regular priceUnit price / per$0.00Sale price $0.00 -

men's jeans 48

Regular price $0.00Regular priceUnit price / per$0.00Sale price $0.00 -

men's jeans 50

Regular price $0.00Regular priceUnit price / per$0.00Sale price $0.00 -

men's jeans 51

Regular price $0.00Regular priceUnit price / per$0.00Sale price $0.00 -

men's jeans 54

Regular price $0.00Regular priceUnit price / per$0.00Sale price $0.00 -

men's jeans 62

Regular price $0.00Regular priceUnit price / per$0.00Sale price $0.00 -

men's jeans 7

Regular price $0.00Regular priceUnit price / per$0.00Sale price $0.00 -

men's jeans 8

Regular price $0.00Regular priceUnit price / per$0.00Sale price $0.00 -

men's jeans with whisker and ripped

Regular price $0.00Regular priceUnit price / per$0.00Sale price $0.00 -

Thigh paint men's jeans 67

Regular price $0.00Regular priceUnit price / per$0.00Sale price $0.00